PLASTICS or METAL?

Reprinted from CHEM! Materials, Processing & Control By George Black, Communications Consultant

During the first half of the last century the decision concerning which material to use for a fluid handling application was relatively simple. Choices were limited to determining which metal would prove most cost effective for the service conditions. Corrosion was the main culprit and all metals corrode. Plastics were not in the equation.

Engineers involved in material selection have extensive laboratory test data to guide them in the selection of the most cost effective metal for pumping chemicals. Once this decision was made by materials engineers, pump selection can be based on a variety of service related items such as product availability, dependability, published product performance, initial cost and an analysis of various maintenance factors. Before long the 18-8 chromium/nickel stainless steel became the industry standard because of their resistance to corrosive fluids. Pumps made with alloys of these materials offered the chemical resistance required for many applications. But there were problems.

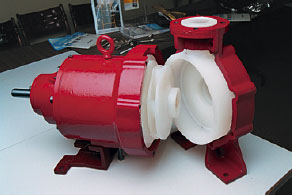

impeller and bearing housing.

thermoplastics.

corrosion resistant metal wasn’t metal.

Chemicals such as bromine and other halogens can destroy metals, even upgraded alloys and special metals like nickel. Capital costs for more exotic metals are unacceptable. In addition, world demands are changing drastically, with processors demanding even stronger corrosion resistance.

Chemical inertness, not just low corrosion rates, has become critical. This adds a new dimension to the material selection decision. The electronic, computer, semiconductor, pharmaceutical, biochemical and medical industries cannot tolerate any metallic contamination whatsoever. This requirement for high product purity, plus the increased need for materials with greater versatility in handling extremely aggressive fluids and mixed chemical waste streams is creating new markets for non-metallics. The standard stainless alloys, the more exotic alloys and special materials such as titanium can no longer satisfy all the needs of industry.

Designers are responding to these critical needs by spearheading the development of pumps made with thermoplastic components. A recent study indicates that plastic pumps — in a variety of configurations and in capacities from fractional metering to 1,450 gallons per minute — are now seeing service in more than 60% of industrial companies. Despite evidence that shows plastic fluid flow systems have economic and quality advantages over stainless steel, habit inhibits actions. In fact, the pharmaceutical and biotechnology industries spend millions of dollars to compensate for the shortcomings of materials of construction (i.e. stainless steel).

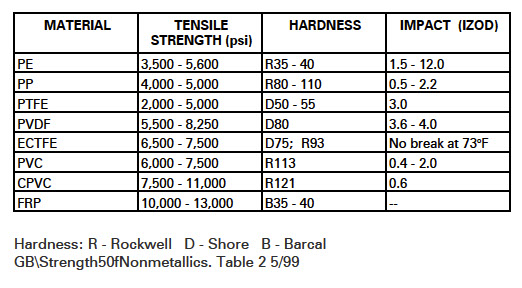

Technical information is critical when determining which non-metallics material to use.

- How do they compare in significant mechanical properties? In terms of tensile strength, hardness, and impact resistance there is no contest. Metals are superior. In vertical pumps and peristaltic rotary pumps these strength factors are not significant, but they can be critical in horizontal centrifugal pump designs. For this reason plastic horizontal centrifugal pumps have molded plastic casings and flanges protected by metal armor to prevent physical damage. This armor offers an additional advantage. It allows thermoplastic ANSI pumps to withstand the same nozzle loadings as metal pumps.

(Table 1) Table 1 – Strength of Nonmetallics Avoid this! This couldn’t happen with thermoplastics. In the fifties we found the ideal corrosion resistant metal wasn’t metal.

- How do they compare in the handling of abrasive fluids?

This is often a surprise to most plant operating personnel who have not had experience with plastic pumps. Abrasion resistance, as measured by weight loss in milligrams using standard Taber laboratory abrasion test equipment, shows that most of the thermoplastics commonly used in pump construction are superior to stainless steel. Only FRP fiberglass reinforced plastic and PTFE show less resistance to abrasion than stainless steel.

- How do they compare in corrosion resistance?

Tabular data comparing stainless steel with the various available plastics is available in many textbooks and corrosion tables furnished by the various product manufacturers. These tables are helpful guides, but they are no substitute for experience. As stated earlier, all metals corrode and the rates at which they corrode are carefully recorded. For the most part, these tests are based on immersion under static conditions. Conditions in the real world are very different, and the dynamic action within a pump can seriously change the result. The thermoplastics, on the other hand, are either inert to the chemicals or they are not recommended. Application data based on installation reports, not laboratory tests, are invaluable. When in doubt check the experience of the pump supplier.

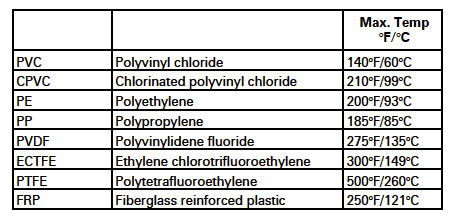

- How do they compare at elevated temperatures? Temperature parameters are not critical for metals, but they are for plastics. As a general rule polyvinyl chloride, polypropylene, and polyethylene cannot be used above boiling, but the fluoropolymers can handle boiling temperatures and higher.

(Table 2) Table 2 – Materials of Construction

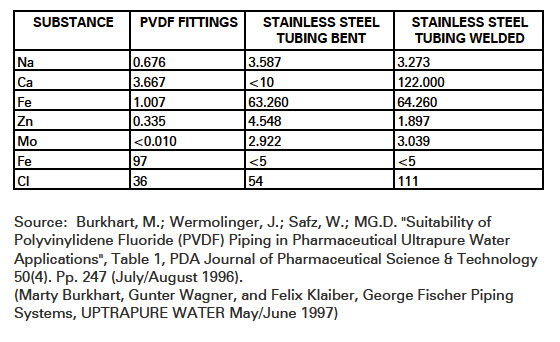

- How do they compare in the avoidance of leaching when handling high purity water?

This is a question raised by the pharmaceutical industry because leaching of piping materials into ultrapure water must be kept to a minimum. This comparison between harmful leaching from type 316 stainless steel and the fluoropolymer PVDF clearly demonstrates the advantages of using plastics rather than metal.

(Table 3) Table 3 – Leaching Comparison Between PVDF and316LSS (ng./mL)

- How do they compare with respect to cost?

The initial cost of a stainless steel piping system and a PVDF system are about the same. A polypropylene system will cost substantially less, assuming it can satisfy the service conditions. But initial cost is only part of the picture. The lighter weight of the plastic units simplified installation, reduces the time involved and minimizes downtime with respect to future maintenance. Threaded joints of plastic components will not seize. Disassembly for any purpose is easier and faster.

Author’s Note: Material selection for pumps and related equipment becomes more difficult as the conditions of service become more demanding. Recent studies have shown that when consideration must be given to the problems involved in handling corrosive chemicals at varying concentrations of the full pH range, or to secure better resistance to abrasion, or to avoiding product contamination, or to reducing the high cost of maintenance and production downtime, thermoplastic pumps are preferred and more commonly being specified by consulting engineering firms. In response to thermoplastics increased acceptance by industrial manufacturing companies, processing firms and utilities, thermoplastic pumps have become readily available on short delivery schedules in standard and custom designs in a wide range of chemically inert materials.